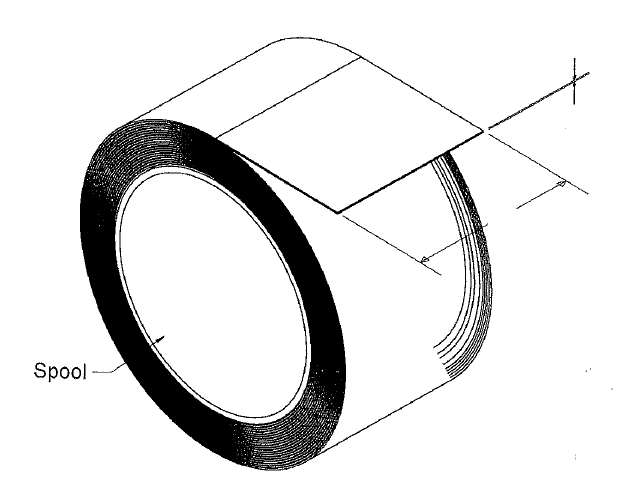

Alumina Tape

Our alumina tape is produced via a roll compaction method. It is rolled in green (un-fired) thicknesses of 0.024” (0.61mm) to 0.058” (1.47mm) and at a single width of 5.875” (150mm). The length of a roll varies with the thickness but is generally between 75 and 100 feet. We sell the tape in its green (un-fired) form for various proprietary applications. It is not intended for final use in its current form, as it contains the binder system used during rolling. It requires either firing to 2,900°F for complete vitrification to a hard-fired substrate, or to be encapsulated within a sheath or other containment with binders removed through an annealing process. During annealing, binders will burn off at a temperature of approximately 800°F and the tape will at that point revert back to a compacted powder.

Alumina Substrates

96% Alumina offers high mechanical strength, low thermal conductivity, excellent electrical insulation, and good dielectric properties and good corrosion and wear resistance. Uses are, but not limited to, electronics, circuit boards, sensor applications and sintering aids. Du-Co manufactures 96% alumina substrates in sizes ranging from very small, custom laser cut designs up to a maximum size of 4” x 6”. Alumina Substrates are manufactured using roll compaction method of manufacturing. The thickness range is .025 – .045. Please contact sales@du-co.com with your specific requirement for quotation